Introduction of Electro-etching Workshop. Art School of Tenerife. September 2008.

For the first time in Spain, Alfonso Crujera set up an electro-etching unit in a formal education center, the Art School Fernando Estévez, Santa Cruz de Tenerife. At the same time, he gave an introductory course to the teachers of this school and other institutes with the objective of including electro-etching as a subject in the school program.

The set up unit is currently ready for electro-etching zinc and copper plates, comprising a power supply of 10 volts and 25 amps, with voltage control and digital displays. Two tanks of polypropylene which can simultaneously etch multiple plates of copper or zinc. The tanks are installed in parallel, with common electrodes for both cells. Grid cathodes of copper and zinc, and electrolytes of copper sulfate and zinc sulfate.

Theory : - History of electro-etching

- Basis of electrolysis

- The

electro-etching unit

Practice: - Setting up the tanks, connection to the power supply, electrodes and cathode grid, preparation of the electrolytes

- Etching on copper and zinc plates using

different varnishes, etching lines, electrotint of open bite

- Application of graphite ink as a varnish to

draw lines, electrotint, soft ground

- Passive electro-etching on zinc plates,

this process does not use electricity and can be practiced without a power

supply

- Masking techniques -litographic pencil,

splashes and drops of liquid resist, galvanizing.

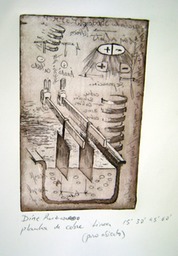

Pictures from the workshop and etchings

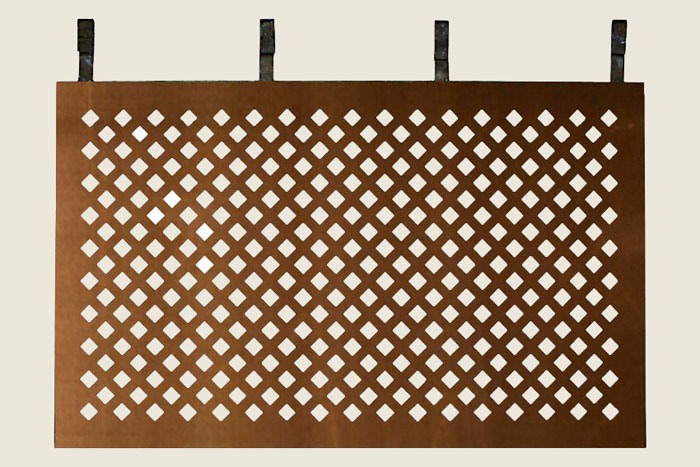

* The picture above is a cathode grid of cooper