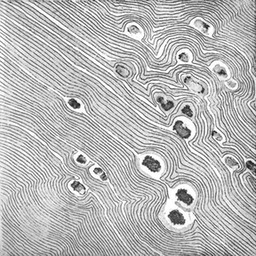

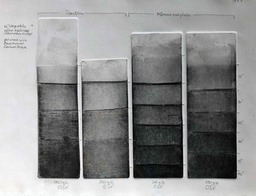

The printmaking artist Bernhard Cociancig attended our workshop-residence for the second time. For a week, he has been working on zinc plates. He wanted to check if the problems he was having with open bites on plates of this metal in his studio would also happen here. It turns out that the zinc etching plates currently supplied in Austria (probably in Spain as well) are not pure zinc, they contain a small amount of titanium (in the range of 0.06 to 0.2%) and copper (between 0.08 to 1.0%) to give the zinc more resistance to corrosion. Obviously these plates are not made for etching, it is a material for industrial and construction use. With pure zinc plates which we artists use, when applying electrolysis to an area of metal unprotected by varnish, a rough surface is produced that retains the ink, providing shades from gray to black without the need to use rosin – which is a great advantage. We call it ‘open bite electrotint’, with a result that it looks like to traditional aquatint. The problem for printmakers who work with electrolysis is that the tonal areas cannot be produced with this alloyed zinc. Drawing lines into the different varnishes and line etches present no problems, however to achieve areas from gray to black tones, we have to use different “tricks” to achieve these effects. And that was what we have been mostly working on this week, checking the titan-zinc plates of Austria and Spain with several concentrations unfortunately giving us the same negative, disappointing results. However we have been using two grounds that we both really like for their great versatility, graphite ink and BIG etching ground, that have given great efects.

Bernhard is also an engineer and he likes to systematize processes. He has left me several of his tables in the workshop to measure electrolyte concentrations, for which I am very grateful. It is also appreciated that he continues to experiment with electrolytic etching and open new possibilities.

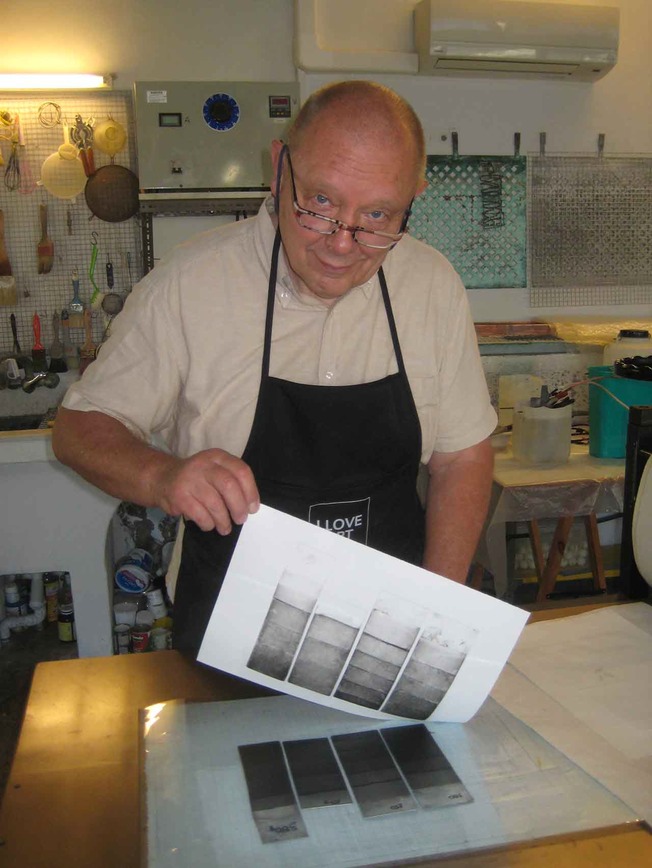

Pictures from the workshop

Bernhard Cociancig speaks about his second experience in the workshop-residency

Diese Woche war bereits das zweite Man, dass ich Gast bei Amparo und Alfonso sein durfte, es fühlt sich bereits an wie ein Teil der Familie zu sein! Obwohl ich mit Alfonso schon im Vorfeld viele Ideen ausgetauscht hatte, kam ich mit dem Plan, exklusiv an Zinkplatten zu arbeiten, nachdem ich in meinem Studio bereits viele (sehr viele!) enttäuschende Tests mit offener Ätzung gefahren hatte und hoffte, dass Alfonso mir zeigen würde, was ich falsch gemacht hatte. Es stellte sich allerdings heraus, dass wir es beide nicht schafften obwohl wir wirklich alle zu Verfügung stehenden Tricks versucht hatten. Der Grund ist sehr enttäuschend: die Hersteller der Zinkplatten haben ihr Rezept für die Legierung abgeändert und setzen dem Zink nun (zwar sehr keine) Mengen an Titan und Kupfer zu. Das ist zwar schön für die Bauindustrie um ihre Dächer und Verblendungen stabiler und haltbarer gegen Korrosion zu machen, für uns Elektroätzer ist es allerdings ein Fiasko. Zumindest die offenen Ätzungen betreffend, denn Linienätzungen funktionieren nach wie vor. Alles in allem war die Woche bei Alfonso aber wieder eine sehr angenehme Zeit und wir haben beide jetzt die Aufgabe vor uns, die Nuss des „Titanzinks“ zu knacken! Ich kann auch sagen, dass dies nicht das letzte Mal war, dass ich bei Alfonso auf Residency war...

------------------------------------ English translation by Bernhard Cociancig --------------------------------------

This residency was the second time I had the pleasure to be guest of Amparo and Alfonso, and I am starting to feel like part of the family already! After having already exchanged a lot of ideas with Alfonso prior to my arrival, I came with the plan to work exclusively on zinc plates this time since after many (very many!) disappointing open etch tests back home in my studio I had hoped, that Alfonso will be able to show me what I had done wrong. As it turned out, we both could not get it to work although we have really tried all tricks of the trade. The reason is very disappointing: the zinc plate manufacturer have changed their recipe for the alloy and are now adding (albeit minor) amounts of titanium and copper in the process. These additions will help the construction industry a lot to make roofing and cladding more stable against corrosion but (obviously) throws a spanner in the works for us e-etchers. At least what open etches concern, as line etches still work very well. All in all, the week with Alfonso was a great pleasure again and we both now have a challenge in front of us to crack the nut of these “TitanZinc” issues! Suffice to say, that I am certain that this was not the last time I have been on the island and in Alfonso’s workshop…

Bernhard Cociancig's electro-etching and tables